Precision Connector Mold Manufacturing

Engineer the Future with Connector Molds Built for Precision, Durability, and Performance.

Fecision delivers custom injection molds, stamping dies and die-casting molds achieving micro-tolerances (e.g., ±0.005mm) for your most demanding electronic applications.

----Who We Are

Your Trusted Partner for Precision Connector Mold Tooling

Fecision manufactures precision connector molds for high-volume production needs. Specializing in injection molds for plastic housing and inserts, stamping dies and die-casting molds for metal housing, pins and terminals, our ISO-certified workshops produce tooling with high tolerances from prototype to full-scale production.

Complete Manufacturing Capability

Comprehensive CNC Machining and Post-processing Techniques

20-year Experienced Engineer Team

Professional Engineers Support DFM and Mold Flow Analysis Needs

Quality Traceablility System

In-Process Inspection with CMM (Coordinate Measuring Machine)

Partner with First-Tier OEMs

Long-term Supplier for Top-tier Enterprises in Connetor Industry

——————————————————————————————————————————————————————————————————————————————————————————————————————

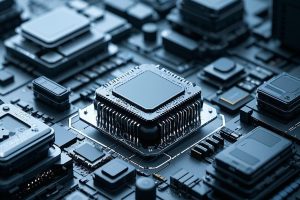

Electronic Connector Molds for Production Needs

Connector, which usually refers to an eletronic connector, is a device that temporarily connects conductive paths to transmit current or signals. Its main parts include plastic or metal housing, terminals/contacts, and some inserts such as insulators or seals.

The two key components of the connector – housing and terminal/contact are generally manufactured through injection molding, metal stamping, and die casting to meet the needs of high precision and fast mass production.

Fecision is deeply involved in the field of precision mold tooling. Based on our years of experience in the connector industry, we can provide customers with customized connector molds to meet their connector production needs.

Molds for Different Connector Parts

Different connector parts may be suitable for different molding methods, which is generally affected by the shape and material of the parts.

Fecision has the ability to process different types of molds and can meet the needs of various connector mold generation.

Metal Housing

complex shell of connector

manufactured through die-casting

Terminal Blocks

components for eletrical connection

manufactured through injection mold

End Cap

cold runner mould

manufactured through injection mold

Backplane Connector

insert molding

manufactured through injection mold

Cage

complex structure

manufactured through stamping die

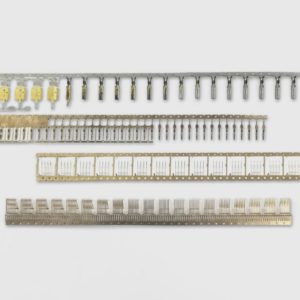

Strip Terminals

high speed up to 1000SPM

manufactured through stamping die

Socket Terminals

high precision contacts

manufactured through stamping die

Pin Terminals

high precision contacts

manufactured through stamping die

Crimp Terminals

round and square contacts

manufactured through stamping die

Comprehensive Mold Tooling Solutions Under One Roof

Our Connector Mold Manufacturing Services

Fecision provides end-to-end mold design, manufacturing, and validation services tailored specifically for the unique demands of the electronic connector industry.

We are your ideal source for both plastic component molds and metal terminal dies.

Mold Design & DFM

Prototyping

Precision Injection Mold Making

High-Speed Stamping Die Making

Materials Used in Mold Construction

Connector products are precision parts that require very high precision. Therefore, when selecting mold materials, it is necessary to comprehensively consider the material’s heat resistance, stability, hardness and other properties.

Different connector products require different mold materials, and the following types are usually selected:

Tool Steel

Stainle Steel

Aluminum

Beryllium Copper

Injection Molding Process for Cable Connectors

The Process of Manufacturing Molded Cable Connectors

Molded cable connectors are devices that provide safe and efficient connections for power and signal transmission, and are widely used in a variety of industries such as automotive, aviation, and industrial equipment. These connectors are usually manufactured using injection molding to ensure tight tolerances, complex geometries, and consistency in mass production.

The key steps of the cable connector injection molding process are summarized below:

1. Material Selection

Choose the right connector material, usually TPE, TPU or polycarbonate, to ensure insulation, durability and flexibility.

2. Mold Design

The mold is usually made of steel or aluminum, and the cavity needs to be designed to correspond to the shape of the cable connector.

3. Heating & Injection

The selected material is heated to a molten state and then injected into the mold cavity under high pressure to completely fill the mold cavity. The mold is usually held under pressure for a few seconds to allow the material to solidify before cooling.

4. Cooling

This step allows the material to harden and form the desired material. The cooling time depends on factors such as material thickness and mold design.

5. Ejection

An automatic ejection system is usually used to eject the cooled molded connector from the mold cavity, and trimming or deburring may be required.

6. Quality Control & Inspection

After the molded cable connector is produced, it needs to undergo a series of quality control tests such as dimensional inspection, mechanical testing and electrical performance testing to ensure that it meets the specification requirements.

If the connector parts are made of metal, they will be subjected to a post-processing process after manufacturing is completed – electroplating. This process actually applies a metal coating to the connector shell to enhance its conductivity and prevent rust and wear. The three most common electroplating materials are:

Olive Drab Cadmium

Eletroless Nickel

Black Zinc Nickel

Key Features of Fecision Connector Molds

Electronic Connector Molds: Engineered for Excellence

Our molds are not just tools; they are precision instruments engineered to deliver superior performance, reliability, and efficiency in your connector production.

Precision & Micro-Tolerance Capability

Our molds are manufactured using state-of-the-art CNC (±0.005mm) and EDM technology, consistently achieving micro-tolerances essential for fine-pitch connectors, complex interfaces, and ensuring perfect part interchangeability across millions of cycles.

Capability for Complex Geometries

From intricate locking mechanisms and ultra-thin walls to micro-scale features and complex core pulls, our advanced mold design and manufacturing capabilities turn your most challenging connector designs into reality. We excel at molds requiring complex sliders, lifters, unscrewing mechanisms, and precision inserts.

Exceptional Durability & Extended Mold Life

Maximize your production uptime and minimize costs. We utilize premium mold steels (e.g., H13, S136, Stavax) selected for your specific application, combined with expert heat treatment and optional PVD coatings.This ensures exceptional wear resistance and corrosion protection.

Advanced Molding Processes

Our molds are expertly designed for insert molding, ensuring precise placement and secure bonding of metal terminals or other components. We also provide robust solutions for overmolding (e.g., sealing gaskets, strain reliefs) and two-shot molding, enabling multi-material or multi-color components.

Mastery of High-Performance

We have extensive experience building molds optimized for difficult-to-mold resins common in connectors (LCP, PPS, PBT, PEI, PEEK, thermosets). Our designs address high melt temperatures, precise temperature control, optimal venting, and specific gate/runner configurations to ensure consistent filling and defect-free parts.

Optimized Production Efficiency

We incorporate advanced cooling channel designs (including conformal cooling options) for reduced cycle times. Precision surface finishes and coatings enhance part ejection and reduce maintenance. Our molds are designed for ease of maintenance and efficient setup.

Key Advantages of Using Molded Connectors

Connectors play an important role in realizing complex functions of electronic devices. They often need to withstand harsh environments and support ease of use, durability and cost-effectiveness. Therefore, it is particularly important to ensure the quality of connector manufacturing.

Compared with other production methods, molded connectors have significant advantages in terms of precision, life, cost and other aspects.

Durability & Longevity

Molded connectors are rugged and highly durable to withstand harsh environments such as extreme temperatures, moisture, and exposure to chemicals.

Consistency & Precision

Forming methods such as injection molding and stamping can achieve high-precision manufacturing to ensure consistent part production.

Compact & Lightweight

Molded connectors are compact and lightweight, and their design can be optimized, making them ideal for applications with limited space.

Cost-Effectiveness

Forming methods such as injection molding and stamping are cost-effective manufacturing methods suitable for high-volume production needs. Molding process can be automated, which reduces labor costs and improves efficiency, achieving cost reduction.

Versatility

Molded connectors can be designed and applied in a variety of scenarios, from simple power connections to complex data transmission systems. Different design solutions can meet diverse product application needs.

Electrical Performance

Molded connectors provide excellent electrical performance based on the high-quality performance of their component materials and manufacturing consistency, providing safe and stable connections even under harsh conditions.

Fecision Mold Manufacturing Network

In response to different service types and diverse business needs, we have deployed suppliers with different manufacturing capabilities.

Delivering Precision Molds Across Key Electronics Sectors

Industries We Serve

We provide high-performance connector molds for critical applications in:

Your Strategic Partner for Connector Mold Success

The Fecision Advantage: Why Partner With Us?

Validated Performance, Guaranteed Quality

Commitment to Quality & Validation

We employ rigorous validation protocols, including in-process and final CMM inspection, steel certifications, heat treat certifications, and comprehensive mold trials (T1, T2...) to ensure your mold performs flawlessly and meets all specifications from the first shot. Trust our ISO-certified quality system.

Start your project now

Request a Proposal

Let us bring your vision to life.

Share your project details, and we’ll craft a tailored proposal just for you.