On-demand Precision Mold Tooling and Parts Manufacturing

- Experience end-to-end service for mold tooling and parts manufacturing.

- From design to production, we deliver tailored, all-encompassing, and top-notch solutions, ensuring faster lead times without minimum order quantities.

Join hands with Fecision to optimize your production process and deliver outstanding products to the market.

Start your project now

ISO 9001: 2015 Certified Processes

In-Process Inspection with CMM (Coordinate Measuring Machine)

ISO 13485: 2016 Medical Device

IATF 16949: 2016 Automotive

AS 9100 Quality Managment Aerospace

Manufacturing Services

Mold Tooling

Whether you’re looking for prototypes, low-volume runs, or large-scale production, our mold tooling services streamline the manufacturing process and deliver cost-effective, reliable solutions.

- Various types of molds, including injection mold, thermoforming mold, stamping die, die-casting mold

- Service life of the molds up to millions of cycles

- Tolerances as precious as ±0.005mm through our advanced manufacturing technology

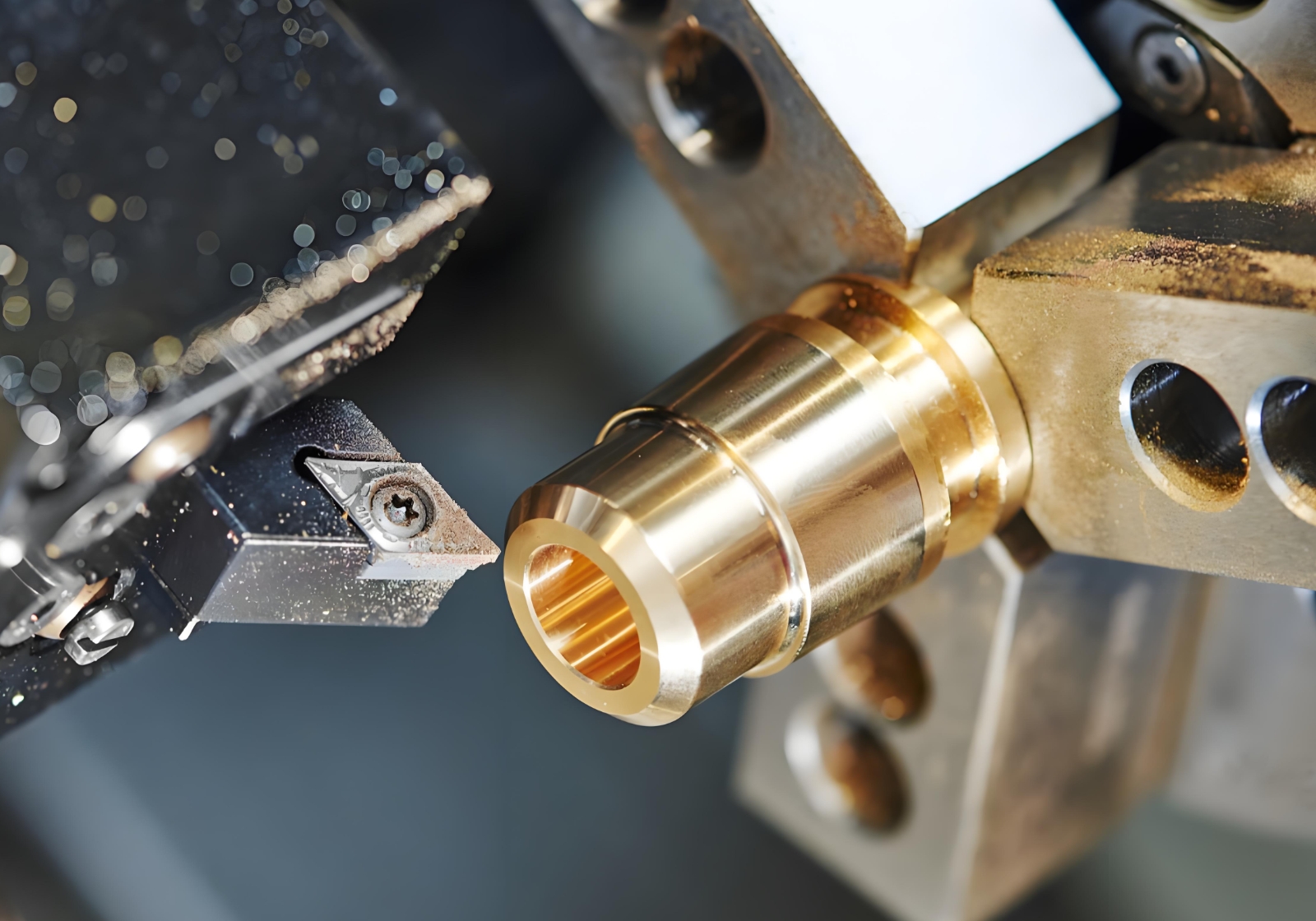

Mold Components

Specialize in the design and manufacturing of high-precision mold parts that enhances mold performance, reduces downtime, and ensures efficient production cycles.

- Lead time of cost-effective, high-quality mold parts as short as 3 days

- Tolerances down to ±0.002mm through our advanced manufacturing technology

- Core technical personnel with at least 20 years of industry experience

Plastic Part Production

Moldability consultation at no charge to help you save both time and money, as well as diverse array of machines, adequate machine quantity and advanced surface treatment technologies to efficiently support mass production.

- Injection Molding

- Thermoforming

- Compression Molding

Metal Part Production

With a robust range of advanced machinery and expertise in various manufacturing techniques, we ensure consistent, high-quality results for every project with quick turnaround times and cost-effective production.

- Metal Stamping

- Die-Casting

- Metal Extrusion

CNC Machining

Our CNC machining process is backed by a rigorous quality control system. With advanced 3-, 4-, and 5-axis machining centers, we consistently meet or exceed client specifications.

- Machined parts with lead times as short as 1 day and a variety of surface treatment technologies to apply.

- Accuracy as precious as ±0.005mm through our advanced manufacturing technology

- Competitive pricing bansed on massive production

Platform Usage and Core Advantages

Let’s Work with Us in 3 Steps

To get started, just choose your targeted manufacturing process and upload your 3D CAD file.

Next, you’ll receive a quote together with design for manufacturing (DFM) feedback within 24h. We are always waiting for you to review the quote and place your order.

Once production is completed with guaranteened quality and quantity, the products will be shipped to you.

Why Choose Us

We Commited to Exceed Your Expectations

Fecision aims at solving customers’pain points and hardships, to help overcome sourcing and manufacturing challenges that have troubled customers for a long time.

Serve Global Customers

Take a Look at What Our Customers Say

How We Protect Your Data

Security at Fecision

Protecting your intellectual property is a top priority for us. All of our partners are bound by strict non-disclosure agreements (NDAs) to ensure the confidentiality of your intellectual property and safeguard the terms of your purchase.

Your data will be transmitted to our servers in an end-to-end encrypted manner. It is up to you to decide whether your data will remain on our servers after production is completed.

We ensure that all documents are stripped of any identifying information about you or your company before sharing them with our production partners.

Industries We Serve

Automotive

The automotive industry shows to focus more and more on technological innovation for enhanced performance, strict quality control to ensure reliability, and coustomized demands in terms of comfort.

Fecision specializes in producing high-quality parts for engine systems, transmission components, interior and exterior elements, and more, using advanced injection molding, die casting, and CNC machining.

Whether for metal parts, plastic components, or composite materials, our state-of-the-art technologies ensure that each part meets rigorous industry standards for performance, safety, and durability, supporting the automotive industry’s need for both innovation and efficiency.

Medical

The medical industry demands parts with exceptional accuracy, biocompatibility, and durability.

Fecision aims to offer expert molding and CNC machining services. Whether it’s custom surgical instruments, prosthetics, or diagnostic equipment, we utilize advanced molding techniques like overmolding and insert molding along with precision CNC machining to ensure perfect tolerances and biocompatibility.

Our experience with FDA-compliant manufacturing and strict regulatory standards ensures that your medical parts are not only functional but also safe and reliable for critical healthcare applications.

Aerospace

The aerospace industry demands components that are lightweight, durable, and capable of withstanding extreme environments.

Our molding and machining services cater to these needs by producing high-performance parts such as turbine blades, structural components, and avionics housings.

We work with advanced materials like titanium, composites, and high-strength alloys, ensuring that every part meets the highest standards of precision and reliability. Our expertise supports you in achieving cutting-edge designs and maintaining the safety and efficiency of your aircraft and spacecraft.

Electronics & Semiconductor

The electronics and semiconductor industry requires ultra-precise components to support the miniaturization and complexity of modern devices.

Fecision specializes in producing intricate, high-precision parts for devices such as semiconductor packages, heat sinks, connectors, and enclosures. Using injection molding, die casting, and CNC machining, we offer customized solutions that meet the stringent demands for performance, size, and thermal management.

Our capabilities support the development of cutting-edge technologies, from consumer electronics to semiconductor manufacturing equipment, helping you innovate and scale efficiently.

Robotics

In the rapidly evolving robotics industry, precision and adaptability are key. Our molding and machining services provide the high-accuracy components needed for robotic systems, including gears, actuators, sensor housings, and structural frames.

We work with a variety of materials to create lightweight, durable, and complex parts that meet the unique demands of collaborative robots, industrial automation, and consumer robotics.

By combining advanced technology with expert craftsmanship, we empower robotics companies to push the boundaries of innovation and deliver smarter, more efficient solutions.

Industrial Equipments

Industrial equipments generally need to withstand the demanding conditions of heavy machinery and equipment.

At Fecision, molding and machining solutions for the industrial equipment industry focus on creating robust, high-performance parts to meet customer’s needs.

Whether it’s gears, pumps, valves, or machine components, our precision CNC machining services deliver tight tolerances and excellent surface finishes, while our molding techniques provide cost-effective solutions for large-volume, complex parts. We help industrial manufacturers optimize their equipment’s reliability, functionality, and operational efficiency.

Got Questions?

Request a Proposal

Let us bring your vision to life. Share your project details,

and we’ll craft a tailored proposal just for you.

Latest Manufacturing Insights

Choosing the Right Injection Molding Process for Your Manufacturing Needs

CNC Machining: Precision Engineering for Modern Manufacturing

Breaking Down Injection Molds: Key Components and Their Functions Explained

Service FAQs

- Metals: Aluminum 6061/7075, Stainless Steel 303/316, Titanium, Brass

- Plastics: ABS, PEEK, Nylon, PTFE, Polycarbonate

- Exotic Alloys: Inconel, Hastelloy, Magnesium alloys

- Mitsubishi 5-axis CNC machines

- CMM inspection equipment (Mitutoyo)

- Temperature-controlled production floors

- Prototyping: 1-50 pcs (72-hour turnaround)

- Low-volume: 50-10,000 pcs (10-15 days)

- High-volume: 10,000+ pcs (scalable production lines)

- Raw material certification

- In-process dimensional checks

- Final CMM/spectrometer verification

- 100% functional testing (per ISO 9001/AS9100)

- STEP (.stp)

- IGES (.igs)

- SolidWorks (.sldprt)

- PDF drawings (with GD&T callouts)

- Optimize wall thickness/draft angles

- Suggest cost-saving material alternatives

- Identify potential tolerance stack-up issues

- NDAs signed before project initiation

- Secure file transfer (256-bit SSL encryption)

- Restricted facility access with biometric controls

- Option for confidential production runs

- Automotive: Die-casting molds, engine components

- Medical: ISO 13485-compliant surgical instruments

- Aerospace: AS9100-certified structural parts

- Electronics: Overmolded connectors, heatsinks