Expert Mold Tooling for Every Need

- Full-cycle service integration: cover design, prototyping, and mass production stages

- Customized modular solutions: adapt to non-standard automotive and medical demands

- Regular progress updates : enable production tracking and rapid troubleshooting

Start your project now

ISO 9001: 2015 Certified Processes

ISO 13485: 2016 Medical Device

IATF 16949: 2016 Automotive

AS9100 Certified Aerospace

No Minimum Order Quantities

In-Process Inspection with CMM

Mold Tooling for Production Improvement

Core Features

Precision & Accuracy

Accurate tooling is essential for consistent and repeatable production runs.

Durability

Material selection for tooling plays a crucial role in the mold's longevity and performance.

Customizability

Mold tooling can be customized to meet specific requirements.

Overview of Our Mold Tooling Services

Mold Design

The mold design is evaluated by our experienced mold engineers to ensure manufacturability, suggesting improvements to enhance quality and reduce costs.

Fecision pays much attention to the critical steps including material selection, tolerance analysis, and DFM validation. We perform detailed mold flow analysis to optimize gate locations, runner systems, and cooling channels.

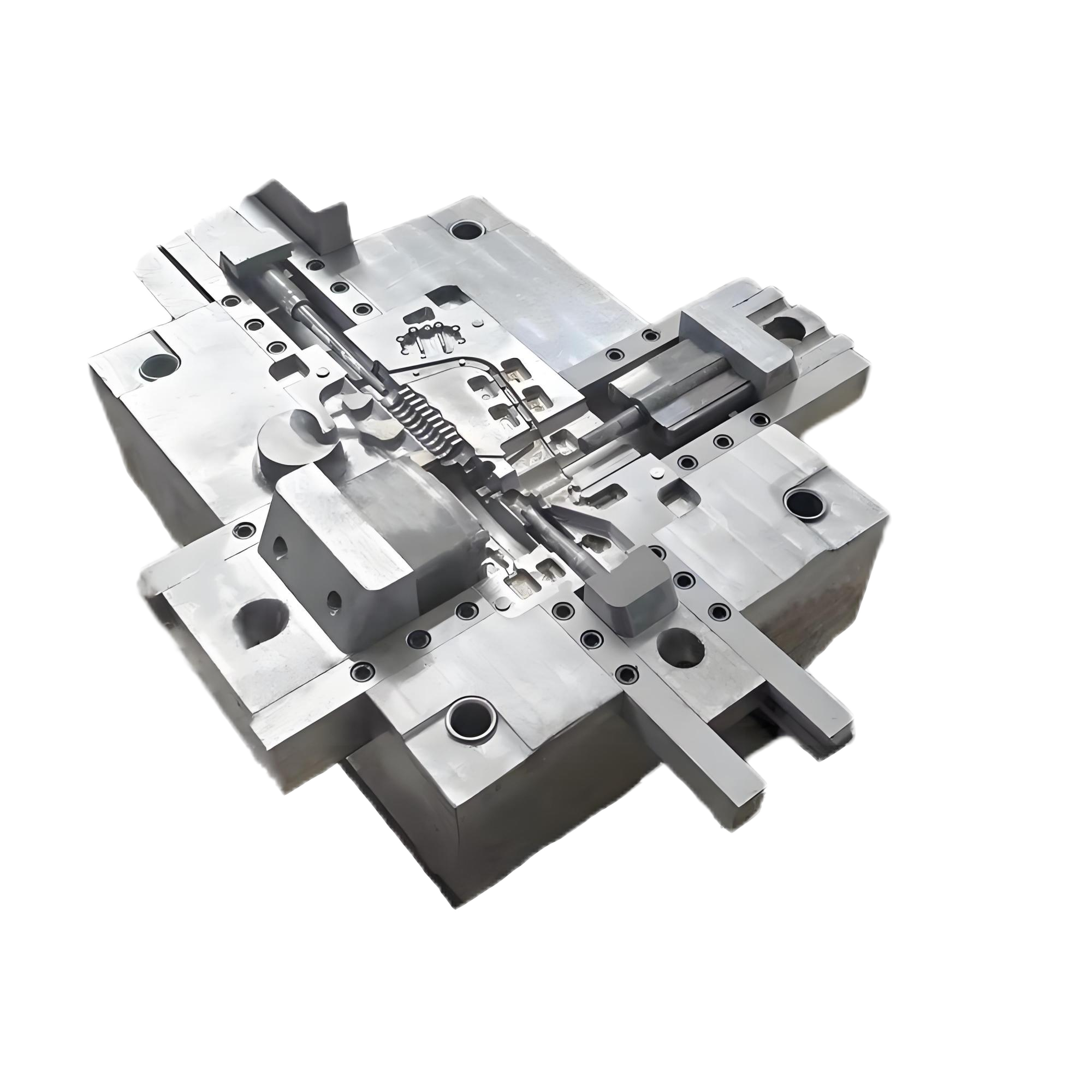

Mold Machining

For high-volume production, we typically recommend hardened tool steels, while prototype tooling may utilize aluminum for faster turnaround and lower costs.

Our skilled toolmakers use advanced CNC machining centers, EDM equipment, and grinding machines to fabricate mold components to precise specifications. We maintain tight tolerances throughout the manufacturing process to ensure proper fit and function.

Mold Assembly & Testing

Our experienced technicians assemble the mold components, carefully checking alignments and clearances. We conduct comprehensive testing, including trial runs, to verify mold performance and part quality before delivery.

We provide inspection reports together with your molds. Our technical team offers ongoing support to maximize mold performance and longevity throughout its service life.

Fecision Mold Manufacturing Network

In response to different service types and diverse business needs, we have deployed suppliers with different manufacturing capabilities.

Comprehensive Mold Tooling Services

Fecision offers end-to-end mold tooling solutions tailored to your specific manufacturing requirements.

Our expertise spans the entire spectrum of mold development, from initial design consultation to final production and maintenance.

Prototyping

Rapid Tooling

At Fecision, our expertise in rapid prototype tooling allows us to quickly turn your designs into functional prototypes or low-volume production molds, significantly reducing lead times and costs compared to traditional mold-making methods.

Our approach is designed to help you bring products to market faster, optimize your designs, and reduce overall production risks. The client was able to identify design flaws early in the testing phase and make adjustments before finalizing the full-scale production mold, saving both time and money.

- Aluminum and soft tool molds for low-volume production

- Rapid turnaround times (as fast as 5-15 days)

- Design optimization for manufacturability

- Cost-effective solutions for concept validation

- Seamless transition to production tooling

Production

Production Tooling

Fecision specializes in precision mold tooling for mass production. Our advanced CNC systems and standardized tooling ensure micron-level accuracy. Rigorous quality control with 3D measurement tools and SPC systems guarantees ISO-compliant output.

Our full-cycle services reduce time-to-market by 30% through synchronized design-to-production workflows. You can trust us to deliver high-performance production molds that will accelerate your manufacturing processes, improve product quality, and reduce costs.

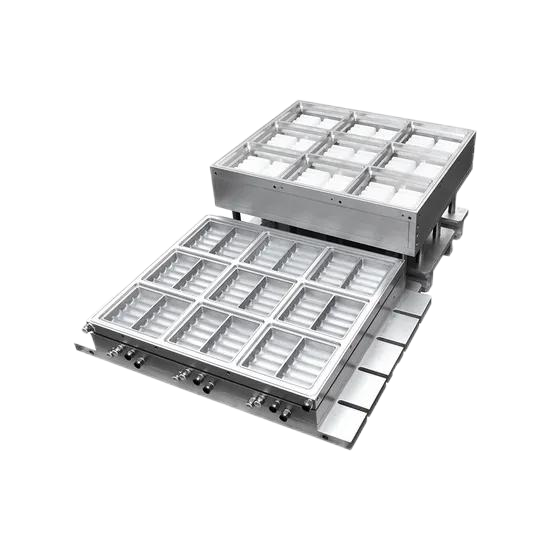

- Hardened steel molds for millions of cycles

- Multi-cavity and family mold designs

- Advanced cooling systems for optimal cycle times

- Precision engineering to tight tolerances (±0.01mm)

- Comprehensive mold flow analysis

Mold Types We Manufacture

Fecision manufactures a comprehensive range of mold types to meet diverse manufacturing requirements.

Our engineering team helps you select the optimal mold design based on your part geometry, production volume, and budget considerations.

Injection Mold

Themoforming Mold

Stamping Die

Die-Casting Mold

Premium Materials for Mold Tooling

The selection of appropriate mold materials is critical to tooling performance, durability, and cost-effectiveness.

Fecision utilizes a wide range of high-quality materials to meet specific application requirements.

P20 Steel

A pre-hardened tool steel widely used for plastic injection molds, die casting dies, and mold bases. Known for its good machinability, toughness, and uniform hardness, P20 offers excellent polishability and wear resistance, making it ideal for precision mold components and tooling applications.

✅ Good machinability, moderate hardness (28-32 HRC)

✅ General-purpose injection molds, medium production runs

✅50,000-100,000 cycles

H13 Steel

A chromium-molybdenum hot work tool steel known for its excellent toughness, high heat resistance, and thermal fatigue strength. Commonly used in die casting, extrusion dies, and hot forging tools, H13 maintains hardness at elevated temperatures, ensuring durability and wear resistance in demanding thermal applications.

✅ Excellent hot hardness, wear resistance (48-52 HRC)

✅ High-volume production, abrasive materials

✅500,000-1,000,000 cycles

S136 Stainless

A high-purity, corrosion-resistant martensitic stainless steel commonly used for plastic injection molds requiring superior surface finish and high polishability. With excellent hardness, wear resistance, and minimal risk of corrosion or staining, S136 is ideal for medical, optical, and high-precision molding applications.

✅ Corrosion resistant, high polish capability (48-52 HRC)

✅ Medical, food-grade, corrosive materials

✅1,000,000+ cycles

NAK80

A pre-hardened mold steel known for its excellent machinability, polishability, and EDM performance. With uniform hardness and good wear resistance, it is ideal for plastic injection molds, precision components, and mirror-finish applications. NAK80 also offers superior dimensional stability and is widely used in high-quality mold making.

✅ Pre-hardened, excellent polishability (40 HRC)

✅ Optical components, consumer electronics

✅100,000-500,000 cycles

7075 Aluminum

A high-strength alloy primarily composed of aluminum, zinc, magnesium, and copper. Known for its exceptional strength-to-weight ratio, toughness, and fatigue resistance, it is widely used in aerospace, automotive, and high-performance engineering applications. 7075 also offers good machinability but limited corrosion resistance compared to other aluminum alloys.

✅ Lightweight, excellent machinability

✅ Prototype tooling, low-volume production

✅ 1,000-10,000 cycles

Beryllium Copper

A high-performance copper alloy known for its excellent strength, hardness, conductivity, and corrosion resistance. Often used in molds, precision tools, electrical connectors, and aerospace components, it combines good thermal conductivity with superior wear resistance, making it ideal for demanding applications requiring durability and precision.

✅ Excellent thermal conductivity

✅ Core pins, inserts for rapid cooling

✅Lifespan varies by application

QC-10 Aluminum

A high-strength, high-hardness aluminum mold alloy known for its excellent machinability, dimensional stability, and thermal conductivity. Commonly used for injection molds, blow molds, and structural components, QC-10 provides fast machining speeds and reduced cycle times, making it ideal for high-volume production tooling and prototype applications.

✅ Stable, stress-relieved aluminum alloy

✅ Bridge tooling, medium production runs

✅ 10,000-30,000 cycles

D2 Tool Steel

A high-carbon, high-chromium cold work steel known for its excellent wear resistance, hardness, and dimensional stability. With strong toughness and edge retention, D2 is widely used for cutting tools, dies, punches, and industrial knives, making it ideal for demanding applications involving abrasive materials.

✅ High wear resistance, dimensional stability

✅ Inserts for abrasive materials

✅ 300,000-800,000 cycles

Mold Tooling Specifications

| Category | Parameter | Typical Value/Range |

| Design | Tolerance Control | ±0.01 mm |

| Mold Cavity Number | 1-128 cavities | |

| Cooling Channel Diameter | 6-12 mm | |

| Machining | CNC Accuracy | ±0.005 mm |

| Surface Roughness (Ra) | 0.4-1.6 μm | |

| Electrode Wear Ratio (EDM) | 0.01-0.03 mm/min | |

| Materials | Common Steel Grades | P20, H13, S136 |

| Hardness (HRC) | 28-52 HRC | |

| Testing | Injection Pressure | 50-150 MPa |

| Cycle Time Optimization | 15-30% reduction | |

| Dimensional Verification | 3D scanning (≤±0.02 mm) | |

| Standards | Mold Base Compatibility | HASCO, DME, LKM |

| Surface Treatment | Nitriding (0.1-0.3 mm depth) |

Custom Mold Making for Diverse Industries

Fecision’s mold tooling expertise serves a wide range of industries, each with unique requirements and specifications.

Our specialized knowledge ensures that we deliver optimal solutions for every application.

Automotive

Our automotive mold tooling meets stringent quality and durability requirements for interior components, under-hood parts, and exterior trim. We specialize in multi-cavity molds for high-volume production and complex geometries.

Medical

For medical device manufacturers, we provide clean room-compatible tooling with exceptional surface finishes and tight tolerances. Our molds support FDA-compliant materials and meet stringent documentation requirements.

Electronics

Our tooling requires high precision, fine detailing, and superior surface finish. It supports the production of connectors, housings, micro components, and chip packaging with strict dimensional tolerances and consistent quality for high-volume manufacturing.

Aerospace

Aerospace components demand exceptional precision and consistency. Our aerospace tooling incorporates advanced cooling systems and wear-resistant materials to ensure part quality and dimensional stability.

Industrial Equipment

For industrial applications, we develop robust tooling solutions that withstand demanding production environments. Our molds support glass-filled materials and deliver consistent performance cycle after cycle.

Robotics

Mold tooling for the robotics industry ensures precision, strength, and durability, producing high-quality components for advanced robotic systems, enhancing performance and reliability in automated manufacturing processes.

----Case Study

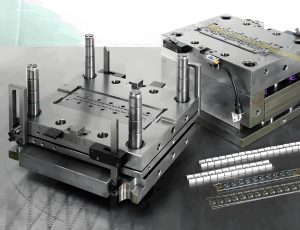

Connector Mold Manufacturing

Connectors, usually referring to electronic connectors, come in many varieties, but the main manufacturing processes include stamping, electroplating, injection molding, and assembly.

The forming/molding process is the key to producing high-quality connectors. By selecting the right materials, making reasonable mold designs, and then using the molding process, connector parts with high durability and consistency can be manufactured to meet the application requirements of various industries such as automobiles, aerospace, and industrial equipment.

Why Fecision for Mold Tooling?

Experienced Team

Our skilled engineers and technicians bring years of expertise to the tooling process, from design and prototyping to the final mold production. We focus on optimizing mold design for long-term performance, minimizing downtime, and enhancing production efficiency.

Advanced Equipment & Technology

We utilize cutting-edge CNC machines, EDM, and precision grinding technology to ensure every tool is crafted with exceptional accuracy. Our manufacturing partners’ equipments are sourced from leading manufacturers, like Sodick, Trumpf, DMG MORI, etc, ensuring the highest standards in mold production.

Quality Assurance

Our molds are trusted by high-profile customers from industries across Japan, Germany, the United States, and beyond, meeting strict and complete quality standard. Access to ISO 9001: 2015 quality certification and our manufacturing partners certified to ISO 13485: 2016, ISO 14001: 2015, and IATF 16949: 2016.

Mold Construction Workflow

Feasibility Assessment

The initial step involves assessing the manufacturablity of the mold. If it's deemed feasible, we proceed with production immediately. If not, we will provide a detailed DFM (Design for Manufacturability) report to the customer.

Design & Flow Analysis

Next, we utilize advanced predictive modeling software to analyze the mold’s performance, ensuring it meets all required specifications. If any issues are identified, we make the necessary adjustments and improvements to guarantee optimal functionality.

Mold Manufacturing & Sampling

The next step is to manufacture the mold using the specified material requested by the customer. Samples are created from the mold to verify that the final product meets the customer's specifications, or to determine if any further adjustments are necessary.

Mold Package & Shipping

Once our engineers confirm the product meets all requirements, it is shipped to the customer. We maintain ongoing communication to ensure the customer is fully satisfied with the product they receive.

Validated Performance, Guaranteed Quality

Commitment to Quality & Validation

We employ rigorous validation protocols, including in-process and final CMM inspection, steel certifications, heat treat certifications, and comprehensive mold trials (T1, T2...) to ensure your mold performs flawlessly and meets all specifications from the first shot. Trust our ISO-certified quality system.

Ready to Start Your Mold Tooling Project?

Together, we can make something remarkable!

Our engineering team is ready to review your requirements and provide expert guidance on the most efficient tooling solution for your application.

Mold Tooling FAQs

At Fecision, quality control for mold production involves precise measurements, thorough testing, and comprehensive validation to ensure the mold meets all specified requirements and is fully optimized for production.

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

The time required to create a mold depends on the design complexity and mold size. Generally, the process spans several weeks to a couple of months.

Yes, Fecision specializes in designing and producing multi-cavity molds for both injection molding and die casting, ensuring high-volume efficiency and consistent part quality.

In many instances, Fecision can modify existing molds to accommodate new parts, depending on the scope of the required changes and the condition of the current mold.

The lifespan of a mold is influenced by factors such as the material used, design complexity, and production volume. Molds made from hardened steel for high-volume production can endure for hundreds of thousands of cycles.

Mold making can support a variety of sizes and complexities. However, exceptionally large parts or complex designs may necessitate specialized tooling and techniques, which could affect both cost and lead time.

Yes, we do! You can access the DFM analysis through the Fecision platform, and you’ll also have the opportunity to comment, annotate, and discuss the feedback directly with a Fecision project specialist—all before placing your order.

We are committed to delivering the highest quality parts right from the start. That’s why Fecision offers DFM analysis at no charge, ensuring you have all the confidence you need before placing your injection molding order.

Fecision does not include mold flow analysis as part of the standard DFM for injection molding. However, we can offer this service as an additional option upon request.

At Fecision, we understand the importance of safeguarding your design IP, particularly when dealing with high-value projects. That’s why our platform is built with top-tier security and confidentiality at its core. From login to file upload to part delivery, you can trust that your intellectual property is protected within our secure Digital Manufacturing Ecosystem.